Application of CNT onto hollow fiber polymeric materials for filtration

Référence

06629-01

Mots-clés

Statut des brevets

US61/829838 priority patent application filed on May 31 2013 and entitled “Application of Carbon Nanotubes or Carbon Particles onto Hollow Fiber Polymeric Materials” and abandoned after PCT due to lack of funding for continuing the development

Inventeurs

Benoit TEYCHENE

Statut commercial

Collaboration

Laboratoire

Institut de Chimie des Milieux et Matériaux de Poitiers (IC2MP), UMR 7285, Poitiers, France

Description

CONTEXT

Water pollution is a major challenge for the coming years and a health issue for many countries.

Several publications have shown that creating planar “carbon nanotubes (CNT) membranes” improves the retention of various pollutants (micro, viruses, heavy metals, etc…). However, the creation of these CNT membranes is not compatible with industrial use of these membranes because they cannot stand backwashing (membrane cleaning by water in the opposite direction of filtration flow).

One reason for the use of CNT in filtration is their high surface area for sorption of chemical and microbial contaminants. Effective for hydrophobic organic chemicals heavy metals, arsenic, pathogens, natural organic matter and cyanotoxins CNT‘surface can easily be functionalized and are chemically stable (eg chloride which prevents biofilm formation). Finally sorption of ions on the CNT is reversible unlike on active carbon which allows to reuse the filter.

These properties and their conductivity also makes it possible to envisage their use for redox electrodes. Furthermore simultaneous electrolysis and filtration have already been shown leading to the destruction of E. coli (bacteria) and the MS2 virus. This conductivity also tracks dirt or damage to the membrane over time without operator control.

TECHNICAL DESCRIPTION

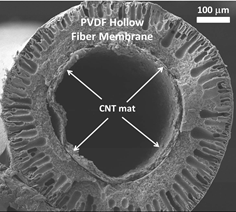

Here the inventors have worked on creating tubular CNT membranes on hollow fibres commonly used in the industry. The creation of the “CNT mat” in the fibres internal hole which gives better structural stability to backwashing without destroying the CNT. This innovation opens up the use of these membranes in more realistic conditions.

DEVELOPMENT STAGE

Fist filtration modules containing 5 fibres (length 10 cm) and 20 fibres (length 30 cm) have been successfully tested

No modification of commercially available membranes. CNT membrane are conductive.

BENEFITS

These filters resist better to clogging and allow a longer life time. Polymer fibres are “on the shelf” and do not require specific treatment. No CNT release.

INDUSTRIAL APPLICATIONS

Water filtration

Example of CNT/polymer fiber

For further information, please contact us (Ref 06629-01)

Besoin de plus d'informations ?

Nous contacterTechnologies Liées

-

08.02.2017

Method for determining the size distribution of a mixture of particles of (macro)molecules using taylor dispersion and associated system

Chimie, Santé / Thérapeutique, Diagnostic médical, Matériaux – Revêtements 00957-03

-

25.03.2015

MOF application: deNOx catalysis

Chimie 02582-01

-

20.10.2014

MOF application: hydrocarbons separation

Chimie 01904-01