Reforming tar in the steam gasification of biomass

Référence

02809-01

Mots-clés

Statut des brevets

French patent application FR0953376 filed on May 20th, 2009 entitled « Catalyseur pour le réformage de goudrons utilisables dans la vapogazéifictaion de la biomasse »

Inventeurs

Alain KIENNEMANN

Claire COURSON

Mirella VIRGINIE

Statut commercial

Research agreement, exclusive or non exclusive licenses

Laboratoire

Laboratoire des Matériaux et surfaces et Procédés pour la catalyse (LMSPC, UMR 7515), Strasbourg France, http://lmspc.alsace.cnrs.fr/

Description

CONTEXT

Since the increase in petroleum price , interest in use of biomass as a partial replacement for fossil fuels via biomass to liquid (BTL) or biomass to gas (BTG) processes is increasing. One of the most crucial problems in biomass gasification technology is the removal of tar, which is a mixture of condensable aromatic compounds. Tar can condense or polymerize into more complex structures in exit pipes, heat exchangers or on particulate filters, leading to choking and attrition This can result in a decrease of total efficiency and increase of the cost of the process. Tar elimination from the gasification product is necessary for any industrial application particularly for Fisher Tropsch or hydrogen use in fuel cells.

TECHNICAL DESCRIPTION

The present invention relates to a catalyst including an olivine substrate on which an iron compound layer is deposited, produced by impregnating the olivine substrate with a solution including an iron salt, and then heat-treating same. Said catalyst is useful for steam-reforming tar, in particular in gaseous media from the steam gasification of biomass. Further, the catalyst can be used alone for catalyzing the steam gasification of organic compounds from biomass while limiting the amount of tar produced in the synthesized gases.

BENEFITS

The catalyst can be used both for the reaction of tar reforming and biomass gasification associated with water gas shift reaction (WGSR). It has the same activity on tar reforming than Ni-olivine based catalysts but presents low friability, no toxicity and lower cost of preparation. It helps to reduce by at least a factor of ten the tar contents of biomass gas and to increase hydrogen contents both by tar reforming and WGSR. It is also effective for ammonia (NH3) and some sulfur compounds removal.

INDUSTRIAL APPLICATIONS

Hydrogen and syngas production, biomass gasification

DEVELOPMENT STAGE

Scale-up of the catalyst has been realized from 20g to 1000kg and the prepared catalyst tested in a 1 MWth fluidized bed pilot plant. Both a significant improvement of gas and hydrogen yield and a drastic decrease of tar and methane content compared to olivine have been obtained in similar operating conditions.

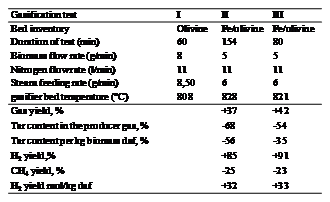

Table 1

Operating conditions of biomass steam gasification tests and percentage variations of the main gasification parameters, with respect to the blank test I (results obtained with the biomass bubbling fluidized of University of Teramo, Italy).

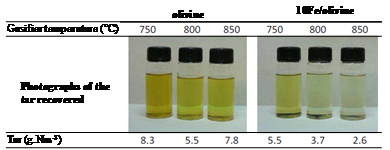

Figure 1

Photographs of the tar recovered after biomass gaisification at different temperatures (results obtained with the bech-scale dual fluidized bed gasifier of National Research Council of Zaragossa, Spain).

For further information, please contact us (Ref 02809-01)

Besoin de plus d'informations ?

Nous contacterTechnologies Liées

-

08.02.2017

Method for determining the size distribution of a mixture of particles of (macro)molecules using taylor dispersion and associated system

Chimie, Santé / Thérapeutique, Diagnostic médical, Matériaux – Revêtements 00957-03

-

04.10.2013

Method and installation for acousto-optical imaging of breast cancer

Matériaux – Revêtements, Optique 86311-01

-

03.10.2013

Composite cement phosphates mixed calcium strontium/injectable microparticles plaga like substitute

Matériaux – Revêtements 86412-01